NEXCAT NA-700: Low odor catalyst in polyurethane materials

Guo Yi

OSiC Performance Materials

Urethane Additives

No.1218, Songsheng Road

201600 Shanghai

China

Research background and significance

Polyurethane materials, as one of the most widely used polymer materials, are applied in various fields such as architecture, decoration and furniture. At the same time, the excellent properties such as comfort and lightweight of polyurethane make it one of the earliest polymer materials used in the automotive field. According to statistics, the use of polyurethane materials in a car such as car seats, pillows, dashboards, cushions, roofs and various interior materials, the total weight of about 19.6 kg, most of which are polyurethane foam. In terms of residential products, polyurethane applications show good comfort. The most commonly used cushioning materials and healthy mattresses that disperse human pressure are made of soft foam. In terms of kitchen supplies, hard foam is applied to insulation products such as refrigerators due to its excellent thermal insulation performance. Polyurethane is used to obtain soft foam materials with different properties to meet the needs. Various additives and different formulations are introduced in production, but this will also lead to an increase in volatile organic compounds. For example, polyether polyols contain some low activity small molecular polyols, polymer polyols contain a certain amount of antioxidants, tertiary amine catalyst to promote foaming reaction and gel reaction catalyst stannous octoate, which are sources of volatile organic compounds.

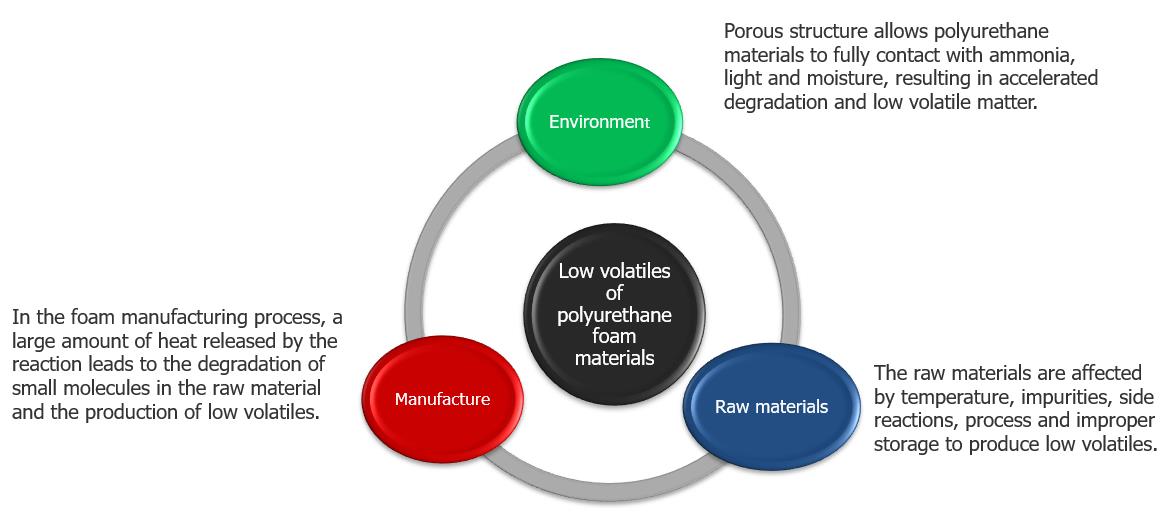

Fig 1 The odor source in polyurethane foam

As people pay more and more attention to health and safety, in order to ensure the air quality in the living environment, in the automotive industry, the major automobile factories have formulated their own quality control standards of organic compounds, and our country has strict regulations on the concentration of organic compounds in the air of the vehicle, especially pentaphenyltrialdehyde. In addition to the concentration of volatile organic compounds, as consumers, attention to car odor is also growing. In addition, in terms of living and home, governments have formulated various standards, and even some enterprises have formulated their own business standards. Table 1 and Table 2 respectively list the national standards for indoor air quality and indoor environmental pollution control standards of civil building engineering.

Table 1 GB18883 - 2002 Indoor air quality standard

|

Controlled substance |

Unit |

standard value |

reference |

|

formaldehyde |

mg/m3 |

0.1 |

Average ( 1 hour ) |

|

benzene |

mg/m3 |

0.11 |

Average ( 1 hour ) |

|

toluene |

mg/m3 |

0.2 |

Average ( 1 hour ) |

|

xylene |

mg/m3 |

0.2 |

Average ( 1 hour ) |

|

ammonia |

mg/m3 |

0.2 |

Average ( 1 hour ) |

|

total volatile organic compounds (TVOC) |

mg/m3 |

0.6 |

Average ( 1 hour ) |

Table 2 GB50325 - 2010 indoor environmental pollution control rules for civil building engineering

|

Controlled substance |

Unot |

Type I building |

Type II buildings |

|

formaldehyde |

mg/m3 |

0.08 |

0.1 |

|

benzene |

mg/m3 |

0.09 |

0.09 |

|

ammonia |

mg/m3 |

0.2 |

0.2 |

|

total volatile organic compounds (TVOC) |

mg/m3 |

0.5 |

0.6 |

Based on the consideration of various factors such as life and health, environment and market, people in the polyurethane industry have made unremitting efforts to develop innovative products such as low-dispersion polyether, reactive catalyst and low-atomized silicone oil. Although these products have a certain role in promoting the reduction of volatiles, there are still many problems to be solved. For example, the reactive catalyst may interact with the chain end of the polymer, leading to the termination of the chain end reaction, resulting in excessive openings of the foam, which destroys the stability of the foaming process and leads to poor physical properties of the polymer materials. While the low VOC catalyst can reduce the volatility of the catalyst, it is difficult to remove the irritant odor. The introduction of a better vacuum filtration device in raw material production removes volatile organic molecules ( such as aldehydes ), but it is difficult to control the small molecules ( such as aldehydes ) produced in the reaction process.

Research methods and results

In this paper, a new type of polyurethane soft foam catalyst NA series catalyst was introduced. The product can simultaneously reduce the odor of polyurethane soft foam, reduce total volatile organic compounds ( T-VOC ) and aldehydes. The comparison between NA-700 catalyst and amine catalyst and the excellent properties of NA series catalysts are described below.

Table 3 Characteristics comparison of NA-700 and A-33 catalysts

|

character |

NA-700 |

A-33 |

|

Appearance |

Transparent slight yellow |

Transparent slight yellow |

|

Odor |

Very low odor |

Amine odor |

|

Viscosity@25℃,mPa/s |

100 |

95 |

|

pH Value |

10 |

12.1 |

|

hydroxyl value (mg KOH/g) |

732 |

557 |

|

VDA270 Standard Test Odor grade |

2.5 |

5.5 |

Test formula and foaming process

Table 4 : Formulas of component A and component B for the preparation of Foam-S and Foam-700

|

|

TM36 |

Foam-S |

Foam-700 |

|

A |

TEP-330N |

80 |

80 |

|

TPOP-3630 |

20 |

20 |

|

|

Water |

3.2 |

3.2 |

|

|

UF-5361 |

0.6 |

0.6 |

|

|

DEOA |

2 |

2 |

|

|

Reactive gel catalyst |

0.7 |

0 |

|

|

NA-700 |

0 |

0.7 |

|

|

Reactive foaming catalyst |

0.15 |

0.15 |

|

|

B |

Modified mdi |

70 |

70 |

Firstly, the material temperature was controlled at 22 °C – 25 °C, and then component A was accurately weighed according to the above formula. The mixture was stirred for 60 s at the speed of 2500 r / min, and then component B was quantitatively poured. The mixture was stirred for 5 s at the speed of 2500 r / min, and quickly poured into the mold box. From the bottom of component B, the time was counted with a stopwatch until the end of exhalation. The foaming time was recorded, and then the finished sponge was obtained after curing. The next test was carried out.

Table 5 : Third-party ( Intertek ) odor test Nissan NES M0160 [ 2016-N ]

|

Sample |

test condition |

Testees |

irritation |

Odor types |

odor intensity |

comfort level |

evaluation results |

|

|

|

|

<1.0 |

|

|

<-1.0 |

|

|

Foam-S |

20℃,50%RH,24HR |

Testee 1 |

0.2 |

Salty fish odor |

2.3 |

-1 |

pass |

|

Testee 2 |

0 |

Foaming odor |

2.2 |

-0.8 |

|||

|

Testee 3 |

0.3 |

Ammonia odor |

2.5 |

-1 |

|||

|

Testee 4 |

0.3 |

Salty fish odor |

2.5 |

-1 |

|||

|

Testee 5 |

0.2 |

Salty fish odor |

2.5 |

-1 |

|||

|

average value |

0.2 |

\ |

2.4 |

-1 |

|||

|

Foam-700 |

20℃,50%RH,24HR |

Testee 1 |

0 |

Foaming odor |

1.3 |

0 |

pass |

|

Testee 2 |

0 |

Foaming odor |

1 |

0 |

|||

|

Testee 3 |

0 |

Foaming odor |

1.3 |

0 |

|||

|

Testee 4 |

0 |

Foaming odor |

1.2 |

0 |

|||

|

Testee 5 |

0 |

Foaming odor |

1.3 |

0 |

|||

|

average value |

0 |

\ |

1.2 |

0 |

|||

|

Foam-S |

80℃,4HR |

Testee 1 |

0.8 |

Salty fish odor |

3.5 |

-1.8 |

failure |

|

Testee 2 |

0.5 |

Salty fish odor |

3.3 |

-1.5 |

|||

|

Testee 3 |

1 |

Ammonia odor |

3.5 |

-2 |

|||

|

Testee 4 |

1 |

Ammonia odor |

3.8 |

-2 |

|||

|

Testee 5 |

0.8 |

Ammonia odor |

3.5 |

-1.8 |

|||

|

average value |

0.8 |

\ |

3.5 |

-1.8 |

|||

|

Foam-700 |

80℃,4HR |

Testee 1 |

0 |

Foaming odor |

2 |

-0.5 |

pass |

|

Testee 2 |

0.2 |

Foaming odor |

2.2 |

-0.7 |

|||

|

Testee 3 |

0.2 |

Foaming odor |

2.5 |

-1 |

|||

|

Testee 4 |

0 |

Foaming odor |

2 |

-0.5 |

|||

|

Testee 5 |

0.2 |

Foaming odor |

2.2 |

-0.7 |

|||

|

average value |

0.1 |

\ |

2.2 |

-0.7 |

|||

The table above is based on a third party ( Tianxiang intertek ) testing, according to Nissan Nissan ' s odor test method to evaluate the odor level of sponges. It can be seen from the results that the overall odor of cotton foam can be significantly improved by using NA series low odor catalysts compared with the standard sample, which can basically reduce a grade directly. In addition, for the detection of foam aldehydes and T-VOC content, the above foams were tested by SGS.

Table 6 : Determination of pentaphenyltrialdehyde in foam by third party ( SGS )

|

Test Data(μg/m3) |

Standard |

Foam-S |

Foam-700 |

|

formaldehyde |

100 |

154 |

56 |

|

acetaldehyde |

50 |

ND |

ND |

|

acrylaldehyde |

50 |

44 |

ND |

|

benzene |

110 |

ND |

ND |

|

toluene |

1100 |

26 |

24 |

|

xylene |

1500 |

12 |

ND |

|

ethylbenzene |

1500 |

32 |

ND |

|

styrene |

260 |

58 |

12 |

|

TVOC(C6-C16) |

|

2842 |

1024 |

In the above table, after using NA-700 catalyst, pentaphenyltrialdehyde was significantly reduced. Especially formaldehyde content decreased by 64 %, T-VOC also decreased by 65 %.

Conclusion

1 : NA series low odor catalysts can effectively reduce the odor grade of polyurethane materials.

2 : NA series low odor catalysts can effectively reduce the content of pentaphenyltrialdehyde and T-VOC in foam.

|

|

Product |

NA-700 |

NA-720 |

NA-830 |

|

catalyst type |

Gel |

●●● |

|

|

|

balance |

|

●●● |

|

|

|

delayed |

|

|

●●● |

|

|

Low odor |

●●● |

●●● |

●●● |

|

|

application |

Slab Stock |

√ |

√ |

|

|

Molded HR |

√ |

|

√ |

|

|

Features |

odorless low volatile gel catalyst. The catalyst can effectively reduce foam odor and volatiles. At the same time, it can improve the opening of cotton foam and help to obtain fine soft hand feeling. Foam can be used in molding high rebound foam, slow rebound foam and other applications. |

Efficient odorless low volatile equilibrium catalyst. The catalytic efficiency is high, which can effectively reduce foam odor and volatiles and improve sponge odor. It can be used in common foam, high rebound foam and slow rebound foam. |

A odorless delayed gel catalyst for molding foams. Help to improve the stability of high resilience foam. Increase foam porosity. |

|

BIOGRAPHIES

Guo Yi

Dr. Guo, born in 1980, Master in polymer materials at Nankai University, PhD in polymer materials at Nanjing University of Technology. Dr.Guo joined GE Toshiba Silicone Corporation ( later Momentive) in 2005 in polyurethane additive product process and production department. In 2010, he joined OSiC and engaged in R&D and production. From 2020 Dr. Guo began to serve as the production director of OSiC Performance Materials.